Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Send Inquiry

Min. Order:1

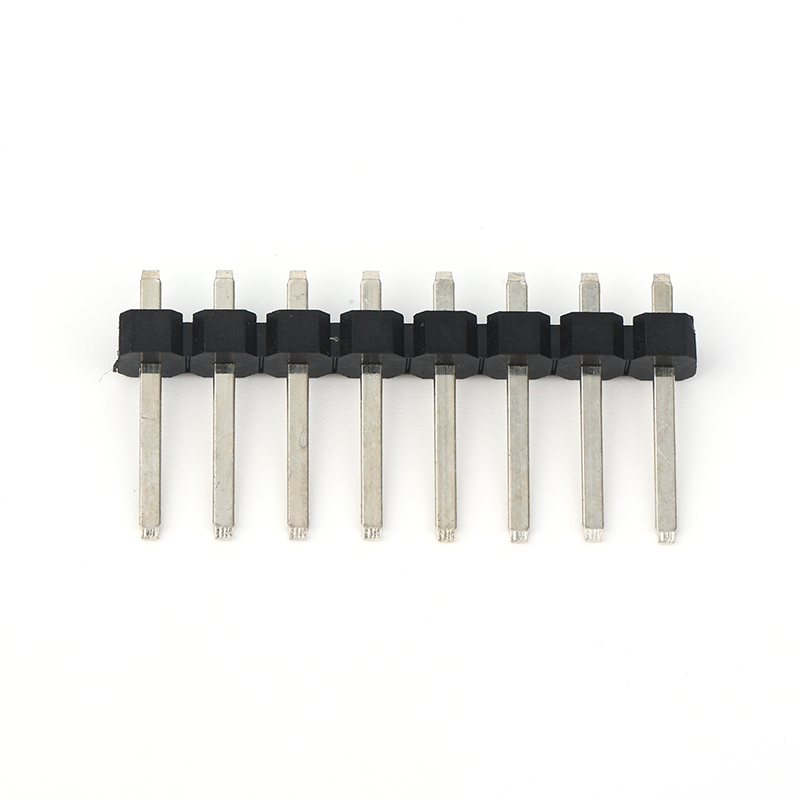

Model No:060369

dgyzconn revolutionizes high-current connectivity with our innovative Pin Header 5.08Mm Pitch system featuring triple-row 180° straight design. Engineered for heavy-duty industrial applications, this modular Connector Pin Header delivers 20A per...

Min. Order:1

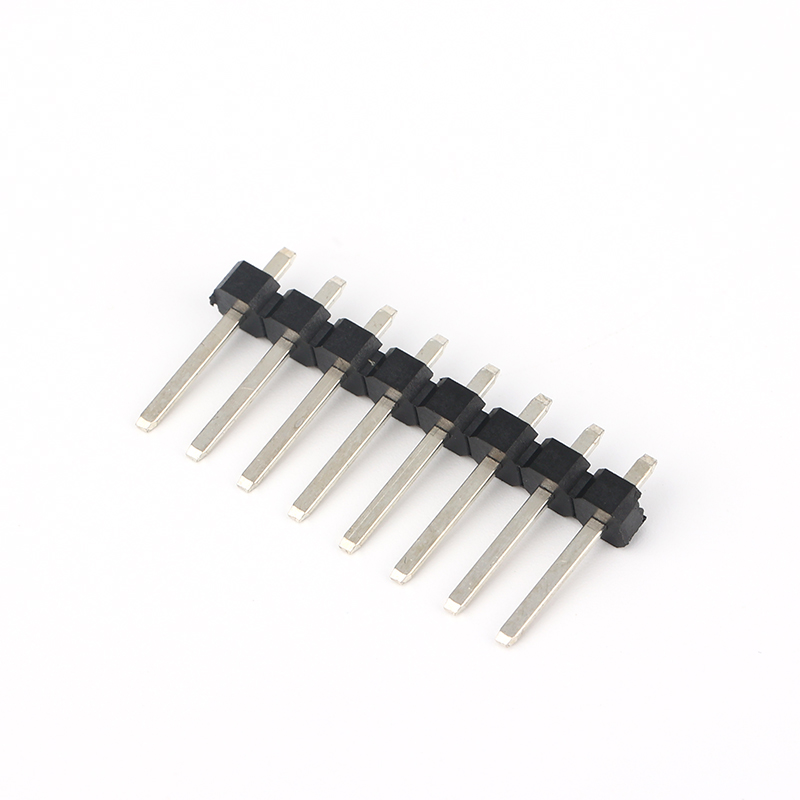

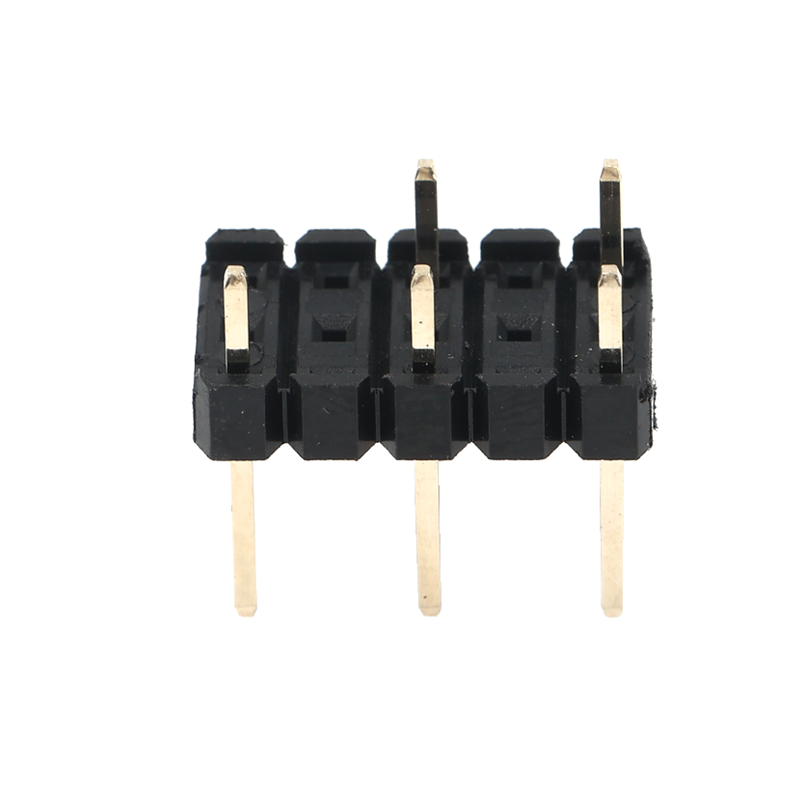

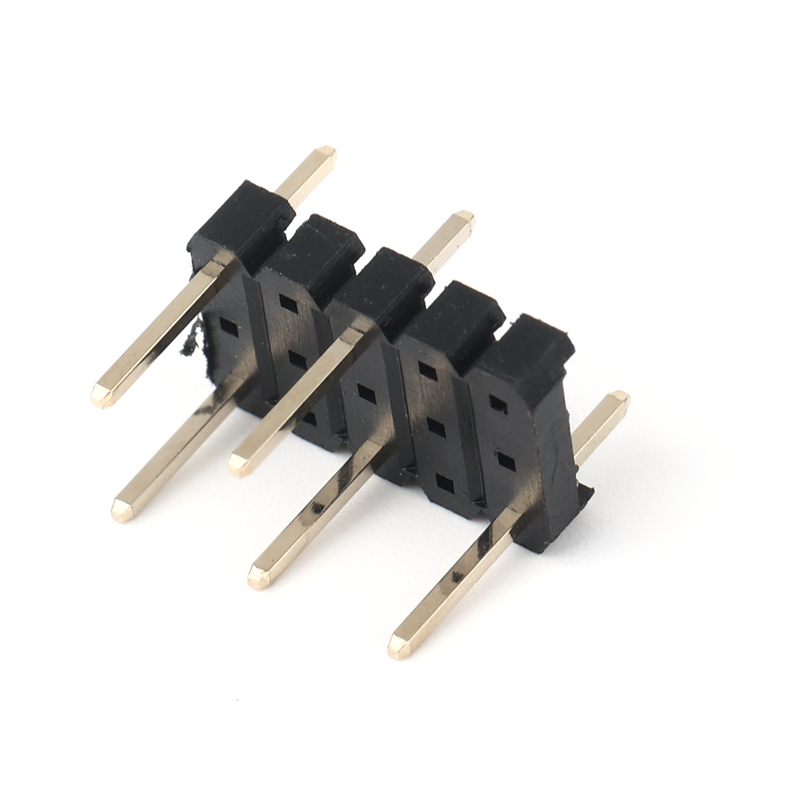

Model No:060368

Experience industrial-grade connectivity with dgyzconn's premium Pin Header 5.08Mm Pitch solution. This single-row 180-degree straight connector delivers robust performance in power transmission applications, featuring gold-plated contacts for...

Min. Order:1

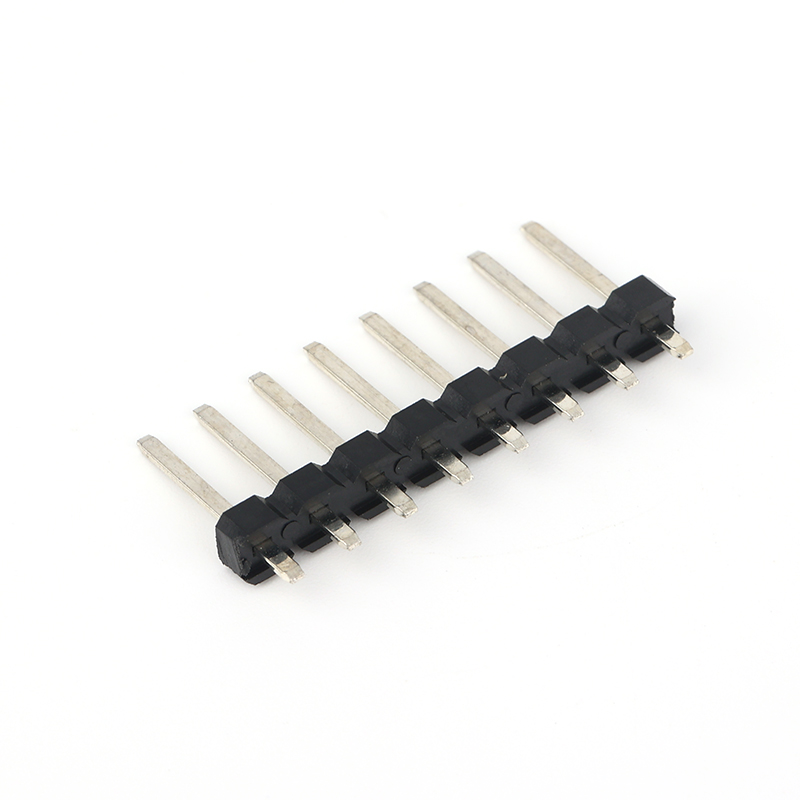

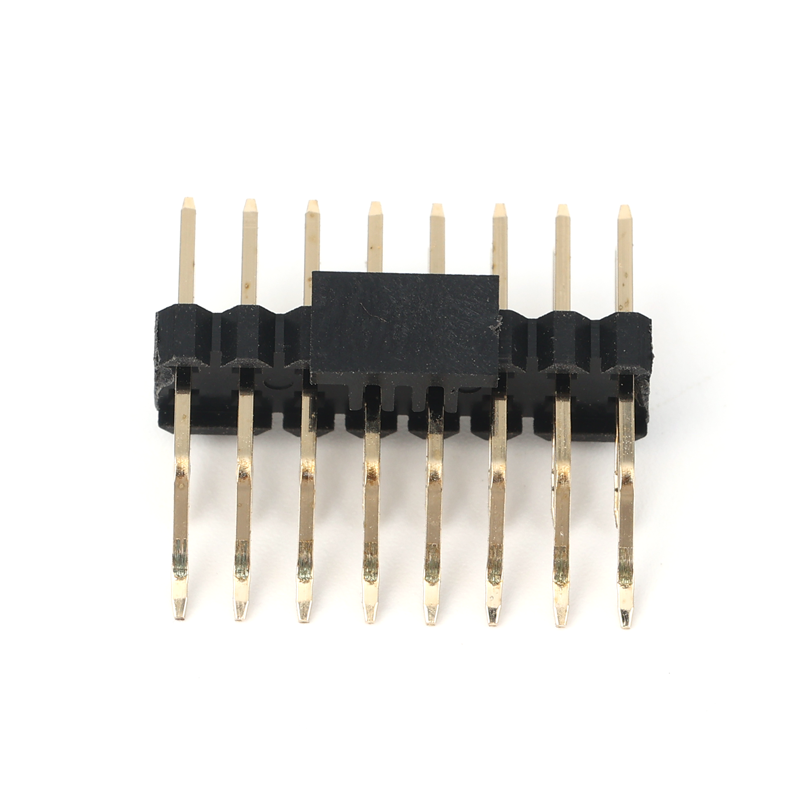

Model No:051403

Product Highlights With a pitch of 5.08mm, this model provides a broader pin separation, which helps reduce the chance of electrical short circuits and offers easier manual soldering and inspection. It is often used in power modules, industrial...

Min. Order:1

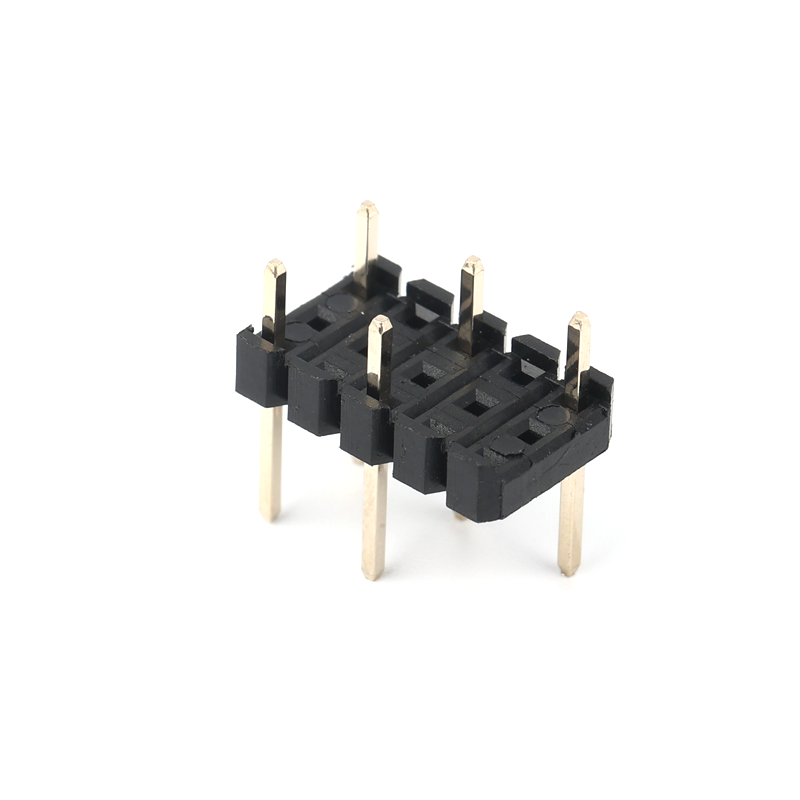

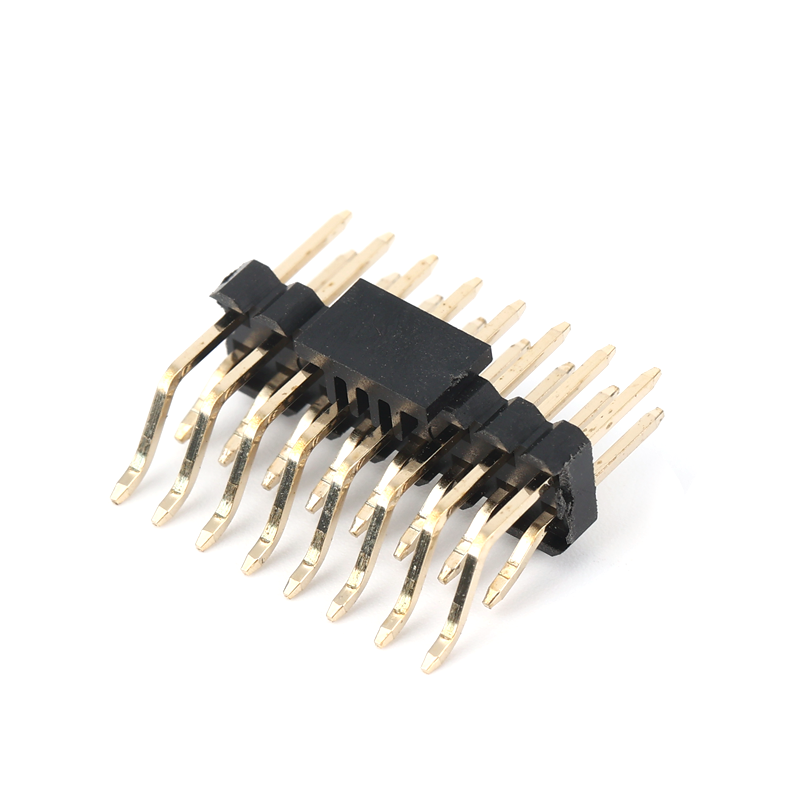

Model No:051419

The 5.08mm Pitch Triple Row Pin Header, configured for 180° straight-through mounting, is a robust and versatile Pin Header Connector engineered for high-power, high-density applications. This unique version includes selective pin removal, allowing...

Product Features

Xometry Instant Engine flower

Xometry Instant Engine flower

Xometry Instant Engine flower

Xometry Instant Engine flower

Technical Highlights

Hot runner optimization design

Laser welding process innovation

Patented stress dispersion design

Copyright © 2026 DONGGUAN YZCONN ELECTRONIC CO., All rights reserved. Privacy Policy

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.