Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Send Inquiry

Min. Order:1

Model No:052306

The Black IDC Type Injector Manifold Customized is designed as a high-performance solution for efficient connection and signal transmission, especially suited for applications in industrial automation, electronics, and automotive sectors. Utilizing...

Min. Order:1

Model No:052314

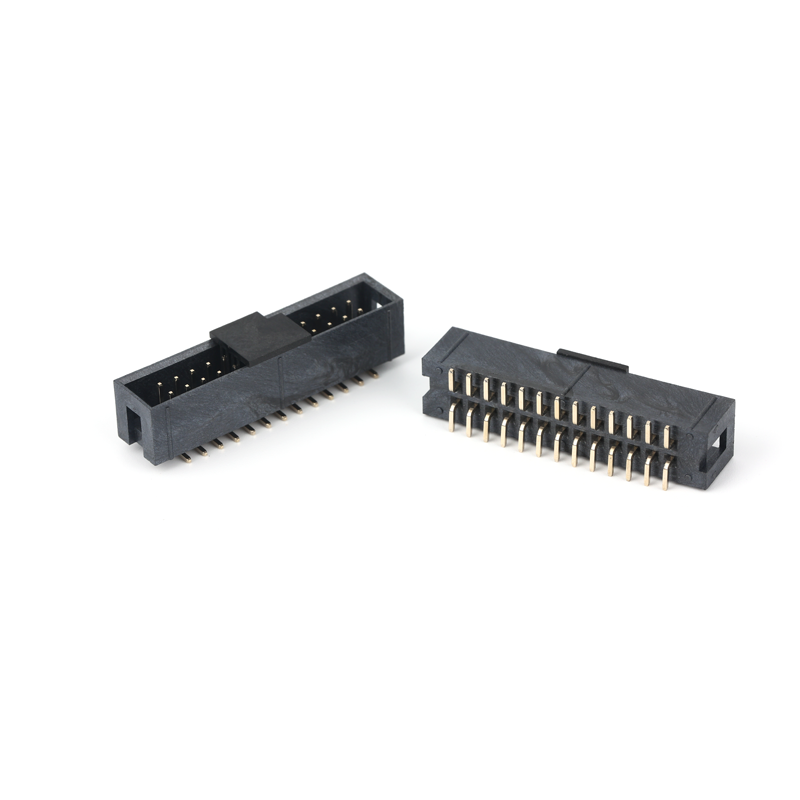

The Two Windows Black Ejector Header IDC TYPE Connector is a high-performance product designed for high-density electrical connections. Featuring a standard 2.54mm pitch and utilizing IDC (Insulation Displacement Contact) technology, this connector...

Min. Order:1

Model No:052312

The 2.54mm Elevated Type Ejector Header IDC TYPE Connector is a high-performance component designed for high-density electrical connections, featuring a standard 2.54mm pitch, and is suitable for various complex electrical systems. This connector...

Min. Order:1

Model No:052308

The Customized Nozzle 2.54mm Injector Manifold IDC Type is an advanced component designed for high-precision electrical connections and fluid transmission applications. Featuring a 2.54mm standard pitch and utilizing IDC (Insulation Displacement...

Min. Order:1

Model No:052307

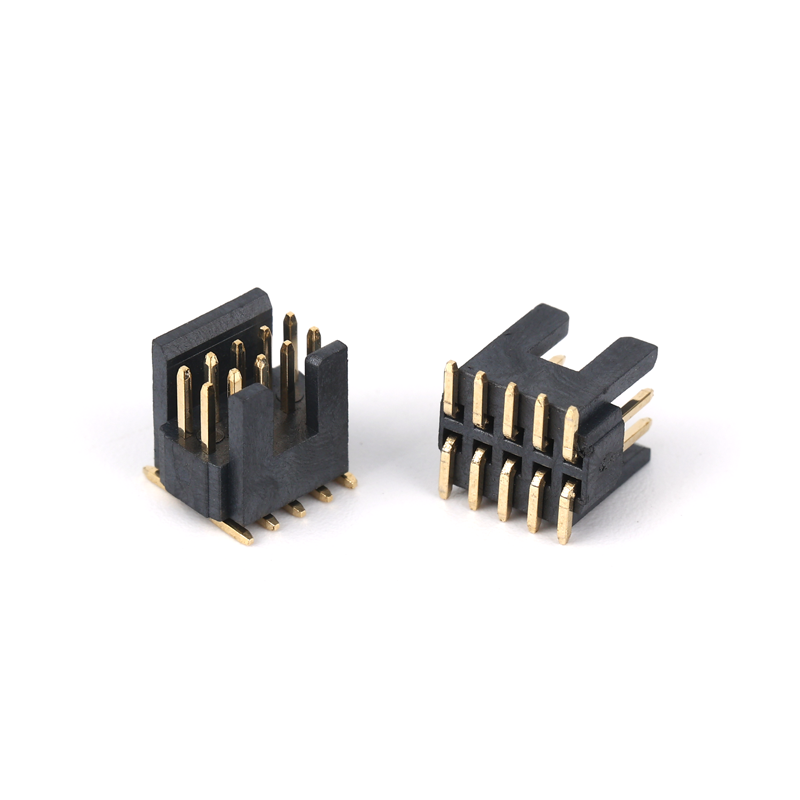

The Ejector Header IDC TYPE Double Row SMT Patch Connector is a high-performance connector designed for high-density electronic systems, widely used in automation, communication, consumer electronics, and industrial control applications. Utilizing...

Min. Order:1

Model No:052315

dgyzconn’s 1.27mm 180 degrees black Ejector Header is the perfect choice for precise internal device connections, widely used in electronics, industrial computers, etc. As part of the Ejector Header IDC TYPE Connector series, its unique 180-degree...

Min. Order:1

Model No:052313

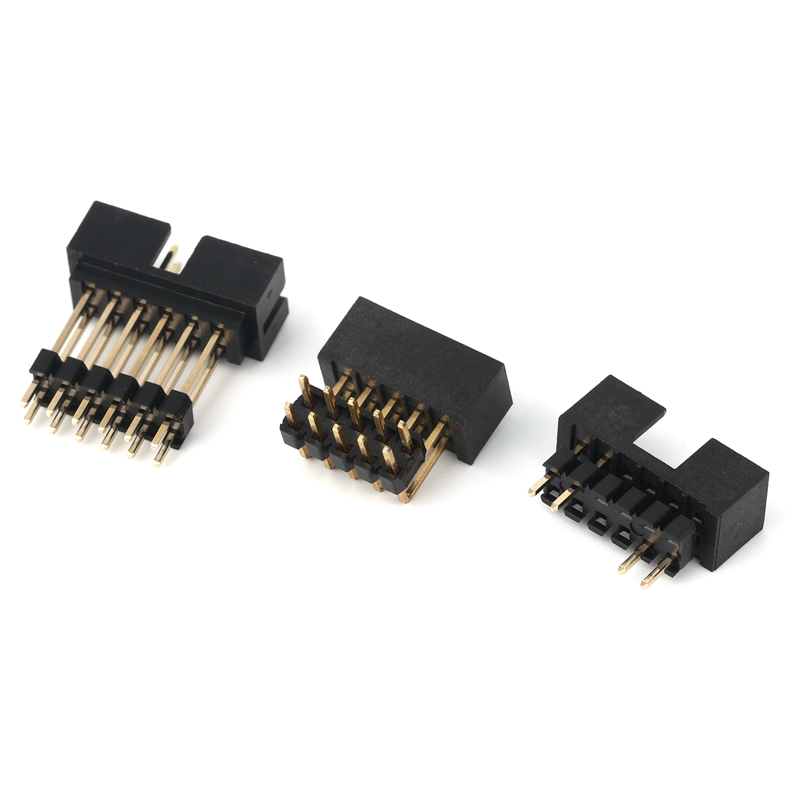

dgyzconn’s Elevated SMT patch Ejector Header IDC TYPE connector is designed for precise internal device connections, an ideal choice for electronics, industrial computers, etc. As part of the Ejector Header IDC TYPE Connector family, its unique...

Min. Order:1

Model No:052311

dgyzconn’s 2.54mm 180 degree Ejector Header IDC TYPE connector is meticulously crafted for precise internal device connections, a reliable choice for electronics, industrial computers, and more. As part of the Ejector Header IDC TYPE Connector...

Min. Order:1

Model No:052310

dgyzconn’s Double row blue Ejector Header IDC TYPE is a top choice for internal device connections. As an Ejector Header IDC TYPE Connector, it suits electronics, industrial computers, etc., working well with SMT soldering and installation methods...

Min. Order:1

Model No:052309

The newly launched 2.0mm Ejector Header IDC TYPE Elevated type by dgyzconn is designed to meet the complex requirements of internal device connections, making it an ideal choice for electronics, industrial computers, communication systems, and...

Copyright © 2026 DONGGUAN YZCONN ELECTRONIC CO., All rights reserved. Privacy Policy

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.